WARSAW — Today in Warsaw, representatives of the Polish private company WB Group and the South Korean defense firm Hanwha Aerospace signed an agreement to establish a joint venture to manufacture missiles for the Chunmoo multiple rocket launch system in Poland.

The agreement for CGR-080 missiles was signed by Piotr Wojciechowski, chairman of WB Group, and Billy Boo-hwan Lee, head of Hanwha Aerospace PGM Business Group, in the presence of senior Polish government officials as well as the Korean ambassador to Poland.

Under the agreement, Hanwha Aerospace will hold a 51 percent majority stake in the new entity, with WB Electronics (a WB Group subsidiary) holding the remaining 49 percent. The joint venture will begin operations following approval from Poland’s Antimonopoly Committee, and also plans to market the missiles to other European customers.

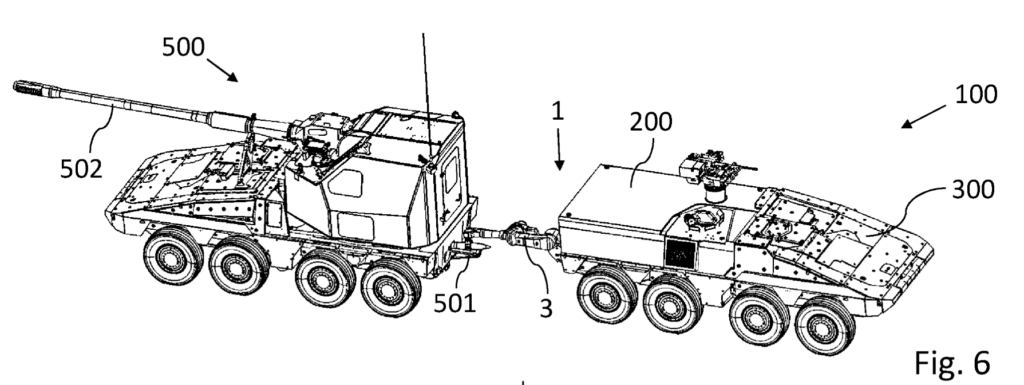

“In 2024, we signed a second agreement for 72 Homar-K [Chunmoo] systems […]. This is the first stage of transferring the production technology of Chunmoo launchers to Poland,” Secretary of State at Poland’s Ministry of National Defense Paweł Bejda said at the ceremony. “The next stage is the production of ammunition, specifically missiles for these Chunmoo launchers. We have an assurance that within three years the first missiles will come off the production line of the company, which has already been established by WB Electronics and Hanwha Aerospace.”