- Reaction score

- 12,704

- Points

- 1,160

The Status of the Navy: Part I

The world has changed immensely since the American Navy's heyday during World War II, but given today's environment, what is the importance of naval power?

patriotpost.us

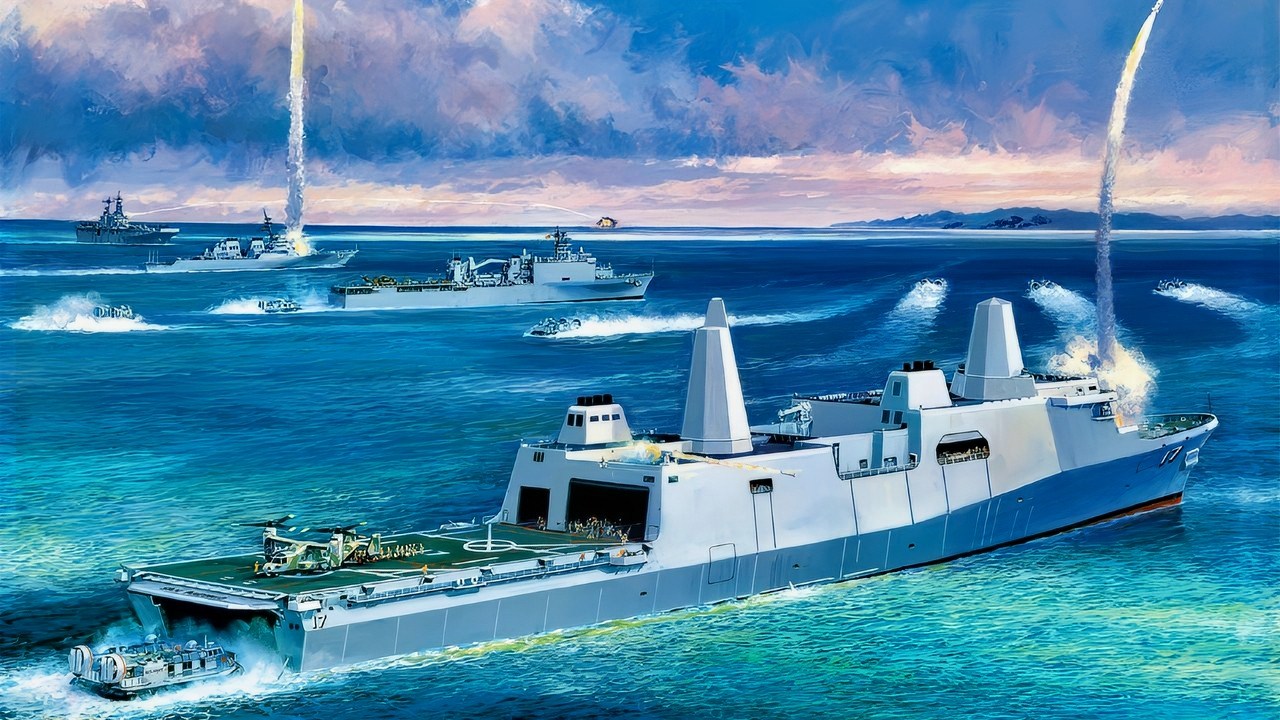

Current Status of the Navy and Shipbuilding

According to the United States Naval Institute, we now have fewer ships than at the end of President Trump’s first term — 293 as of July 21, four fewer than when President Trump left office in 2021. The actual numbers are worse than that. With 293 ships in commission, the reality is that 20%-25% of them at any given time are not deployable. The Navy aims to achieve 80% deployability by 2027. So, the real number of ships we have is roughly 234.

According to the secretary of the Navy, all current shipbuilding programs are missing deadlines and are overbudget despite promises to improve.

The Status of the Navy: Part II

Beginning with an assessment of U.S. shipbuilding capability and working toward evaluating the real threat coming from Communist China.

patriotpost.us

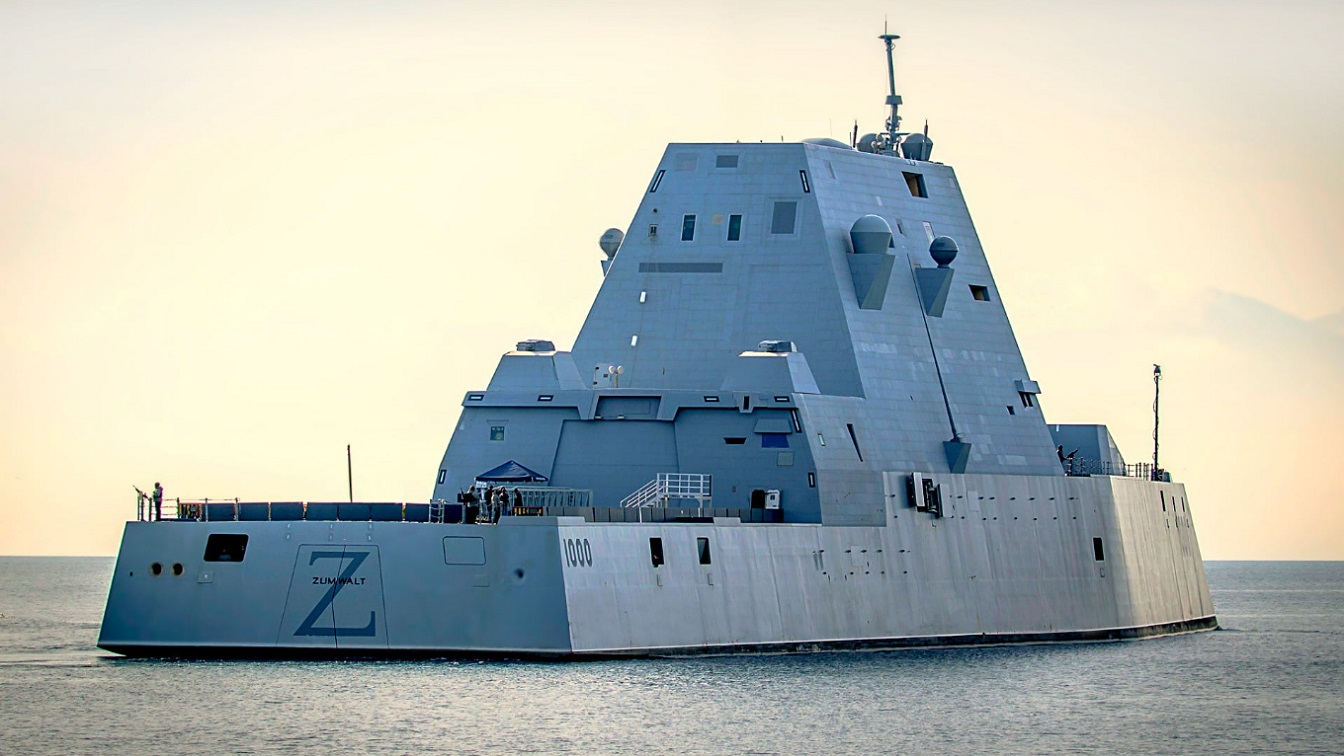

The U.S. Government Accountability Office (GAO) has reported that Navy shipbuilding programs have routinely exceeded their budgets and schedules. For instance, the Zumwalt-class destroyer program experienced a total cost of $24.5 billion for three ships, averaging about $8 billion per ship, which was significantly higher than initial estimates.

A 2024 GAO report indicated that the Navy’s ship design practices often lack alignment with leading commercial practices. This misalignment contributes to delays and cost overruns, as projects proceed without a full understanding of design maturity and readiness for construction.

The GAO has also identified that U.S. shipyards face significant workforce shortages and aging infrastructure. These issues hinder the ability to meet the Navy’s shipbuilding goals, with fewer than 40% of ships completing repairs on time, even when space is available in shipyards.