MilEME09

Army.ca Fixture

- Reaction score

- 7,153

- Points

- 1,210

actually with strike drones this could workWell yes, but no

actually with strike drones this could workWell yes, but no

KS-III with VLS enters chatactually with strike drones this could work

It takes several months to re-tool an auto assembly plant from one platform to another. No clue how long it would to re-tool from manufacturing automobiles to something completely different.Yes, but…

You need some very specific items to make things like comms, FCS, EO/IO items.

Heck even armor isn’t just RH steel anymore.

IIRC South Africa and Israel have found ways to arm themselves. I am sure we could do the same, provided the will was there.It takes several months to re-tool an auto assembly plant from one platform to another. No clue how long it would to re-tool from manufacturing automobiles to something completely different.

With increased automation, whether or not robots, comes increased reliance on chips and other critical components. We have off-shored most of that. If the balloons go up, where will we get them from and how will they get here?

I think you guys found Dental and Healthcare more important than the free world…IIRC South Africa and Israel have found ways to arm themselves. I am sure we could do the same, provided the will was there.

And that's the issue. It's probably better to have a fire extinguisher on the wall than run off to Canadian Tire when the fire starts. The politicians have no will because the voting public doesn't make them.IIRC South Africa and Israel have found ways to arm themselves. I am sure we could do the same, provided the will was there.

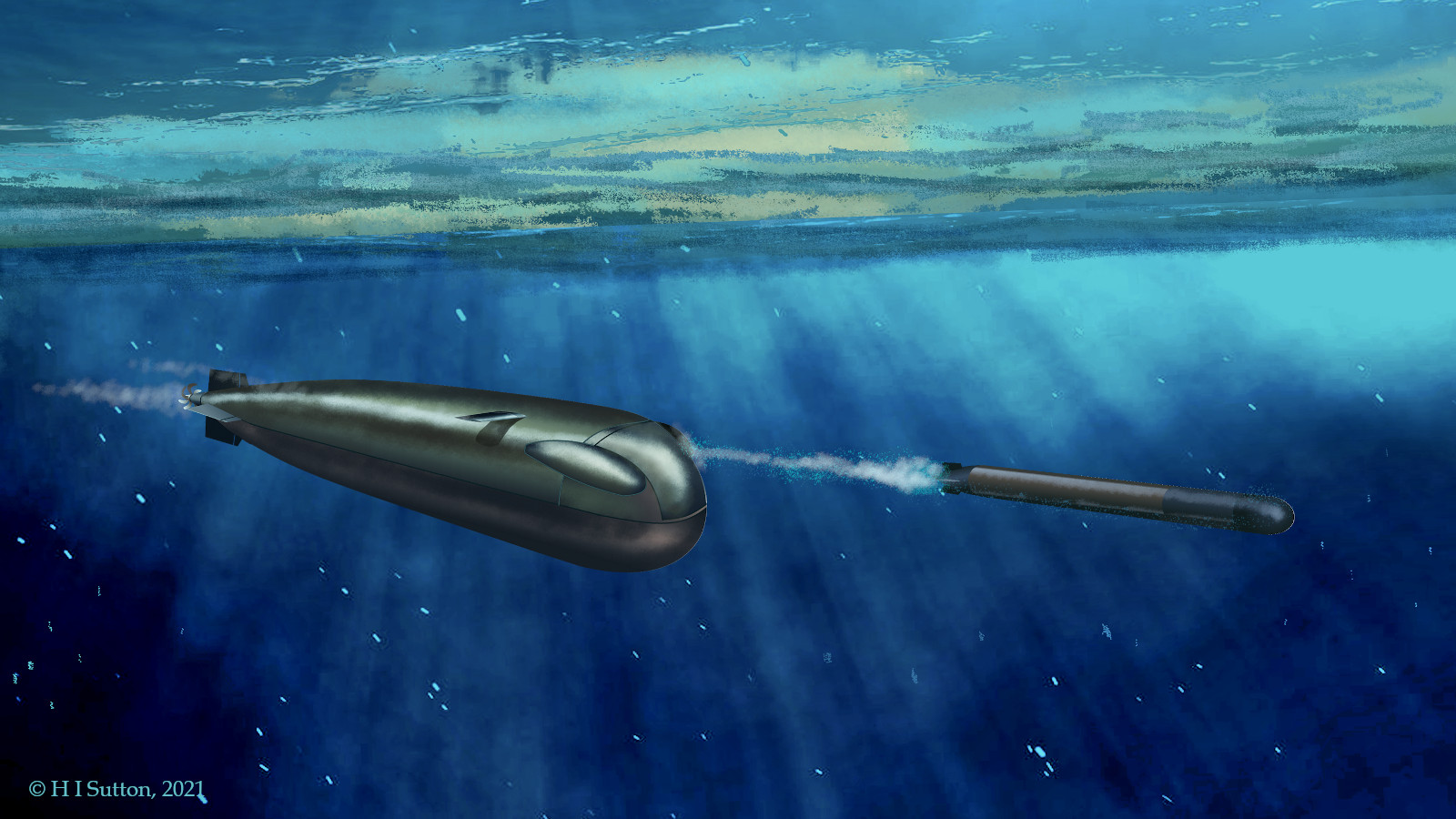

It's already been tested...actually with strike drones this could work

Had a visitor in Halifax a few days ago.View attachment 85395View attachment 85394View attachment 85393View attachment 85391View attachment 85392

View attachment 85390

This class of submarines was acquired by Portugal to replace the previous submarines of the Albacora class, then being operated by the navy. Originally, HDW proposed the Type 209 submarine (U-209) during the competition, but decided to later enter a new proposal based on the Type 214. It is for this reason that the Tridente class is commonly designated as the U 209PN.

The Tridente-class submarines are wrongly classed in the "diesel-electric" class. Their propulsion is exclusively electric, with electric motors powered by batteries. These batteries may be charged while submerged by "fuel-cells" (inverse electrolysis) for which, this submarine carries a huge supply of liquid oxygen and hydrogen. Also, and solely as a second solution for recharging the batteries, this submarine carries two powerful diesel-electric generators (1,000 KVA) for use only when surfaced, or at snorkel depth.

| Type | Attack submarine |

| Displacement |

|

| Length | 67.7 m (222 ft 1 in) |

| Beam | 6.35 m (20 ft 10 in) |

| Draught | 6.6 m (21 ft 8 in) |

| Propulsion | Diesel-electric, fuel cell AIP, low noise skew back propeller |

| Speed |

|

| Range | 12,000 nmi (22,000 km; 14,000 mi) at 8 knots (15 km/h; 9.2 mph) |

| Endurance | 45 days |

| Test depth | superior to 300 m (984 ft) |

| Capacity | 14 |

| Complement |

|

| Sensors and processing systems |

|

| Armament |

|

Probably the most publicized AIP development has been the Italian toroidal design.[1][2] This design by Maritalia provides a unique oxygen storage system for a small submarine that will have a toroidal, double-hull configuration. Although the 02 is held as a gas under pressure, the double-hull design provides a considerable storage capacity. The AIP exhaust is a major consideration and the Italian firm has not published details of its operation; the C02 exhaust is probably compressed for storage in the vacated 02 spaces or pumped overboard. The compression requirements reduce the efficiency of this system.

Two small submarines, a 120-ton craft launched in 1978 and an 80-ton craft launched in 1982, have previously tested the Maritalia system. A new, 157‘/2-foot submarine built for the Maritalia system will have some 40 mw-hours of usable energy for non-snorkel operation.

The Fincantieri shipyard is cooperating with Maritalia to design a toroidal submarine of some 300 tons that could serve as a larger technology demonstration craft. Details of the toroidal design are being closely held by Maritalia, but it seems highly questionable at this time if the system will successfully scale up to a propulsion plant for a full-scale submarine.

…so, not ARes or uniforms?Are we still talking a submarine replacement?

Na stay in theme, NAVRES and dress uniforms…so, not ARes or uniforms?

Na stay in theme, NAVRES and dress uniforms

We make Chips here in Canada both potato and micro. So that should not be much of a problem.It takes several months to re-tool an auto assembly plant from one platform to another. No clue how long it would to re-tool from manufacturing automobiles to something completely different.

With increased automation, whether or not robots, comes increased reliance on chips and other critical components. We have off-shored most of that. If the balloons go up, where will we get them from and how will they get here?

Oh yes Canada loves free stuff.....except its not free....I think you guys found Dental and Healthcare more important than the free world…

Mandatory turning in of everyone's frontload washing machines for the the chips....It takes several months to re-tool an auto assembly plant from one platform to another. No clue how long it would to re-tool from manufacturing automobiles to something completely different.

With increased automation, whether or not robots, comes increased reliance on chips and other critical components. We have off-shored most of that. If the balloons go up, where will we get them from and how will they get here?

Jurgen Prochnow in "Das Boot"

So…how about those submariners’ white turtlenecks?

So, what, when the world, particularly the automotive manufacturing stream, pretty much shut down during COVID because of a chip shortage, we could have solved everybody's problems but nobody asked? People really didn't have to take delivery of vehicles with functions not working because of a lack of chips? Who knew.We make Chips here in Canada both potato and micro. So that should not be much of a problem.

as for retooling plants, things can happen pretty quick if they need to. You can start off manufacturing the old way until the robots and such can be reprogrammed/ installed.

It might be time for Canada to look at what capability we currently have and what can we have going in a month or two.

In a sudden emergency, it will be easy to take over existing plants run by hostile state actors. The challenge is with the automation, they could be remotely hacked and conduct self sabotage or just shut down.. Even with the few auto assembly plants we have, probably half are Canadian subsidiaries of offshore companies and I wonder if an emergent relationship has even been thought of.