daftandbarmy

Army.ca Fossil

- Reaction score

- 43,874

- Points

- 1,160

yup know it well. The two GM plants in Canada at onetime also did that.

I find people outside of the industry don't really understand the size. The complexity, size, competitiveness and the full scope of the automotive industry. When Ottawa puts a bid out for Postal trucks, or army trucks etc.

I was having drink one night at an industry conference not automotive one for my after work job job. My much larger public owned competitor says to me "who are you people? We have put everyone else out out of business or bought them you guys don't die." I said to him I'm from Windsor and we do the Car business and every other business and/or industry in the world is easier.

Amen to that, and thank Gawd that Ford (and the others) are on our side

How Ford's Willow Run Assembly Plant Helped Win World War II

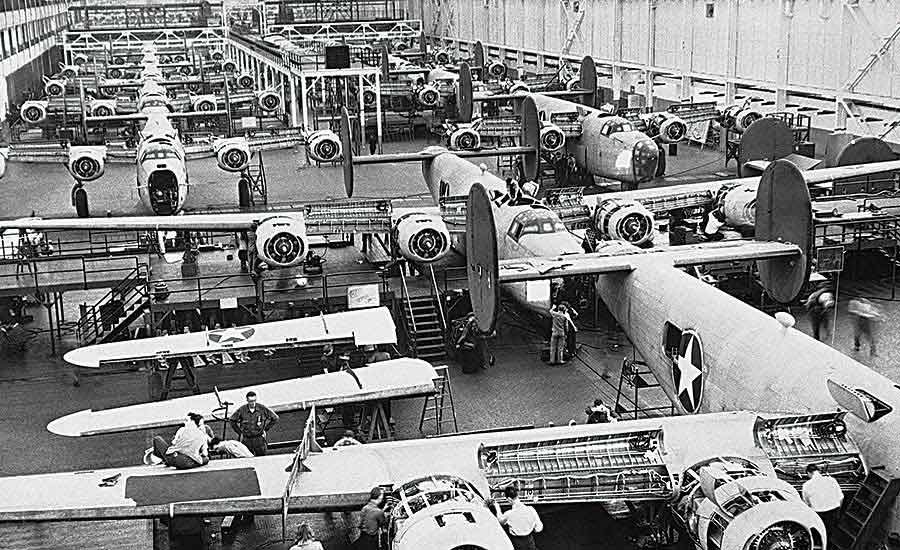

The Willow Run bomber plant made aviation, industrial and social history—along with new B-24s by the hour.

President Roosevelt stunned millions of listeners when he announced during a May 26, 1940, fireside chat that government must “harness the efficient machinery of America’s manufacturers” to produce 50,000 combat aircraft over the next 12 months to confront the “approaching storm” of global war. FDR’s goal exceeded the total of all planes built in the U.S. since the Wright brothers’ 1903 flight at Kitty Hawk, NC, and he challenged the aviation industry to match that number in succeeding years. As he spoke, the country had fewer than 3,000 warplanes in its arsenal, most obsolete.

The president and his advisers were convinced that long-range, high-altitude heavy bombers would be the decisive weapon in a war dominated by air power and industrial muscle. Their shopping list included 12,000 of these aerial battleships to attack Germany’s heartland, hammering military installations, bridges, factories, rail yards, fuel storage tanks and communications centers. The “heavies” of choice were the B-17 Flying Fortress from Boeing Airplane Co. and the B-24 Liberator from Consolidated Aircraft.

The B-17 had a six-year history of design, development, testing and limited production. The twin-finned, high-winged B-24 with its dual bomb bays and tricycle landing gear debuted in 1939 as a repurposed land model of Consolidated’s bulky flying boats. Handcrafted versions were pressed into service in England, but the San Diego company lacked resources and methods for high-volume production of the largest, most complex airplane ever designed. Still, aviation industry leaders scoffed when the War Department chose Ford Motor Co. to mass-produce Liberators.

Automobiles of the era had 15,000 parts and weighed around 3,000 pounds. Sixty-seven feet long, the B-24 had 450,000 parts and 360,000 rivets in 550 sizes, and it weighed 18 tons. Skeptics dismissed mass production of a plane this enormous and advanced as a carmaker’s fantasy that would crash and burn when repeated design changes disrupted assembly lines and junked expensive tooling. “You can’t expect a blacksmith to make a watch overnight,” sniffed Dutch Kindelberger, president of North American Aviation.

Ford proved them wrong, not easily nor entirely, during a 2.5-year production run in a 3.5-million-square-foot factory built over Willow Run Creek near Ypsilanti, MI. The massive plant turned out 8,645 Liberators vs. 9,808 manufactured by four factories of Consolidated, Douglas Aircraft, and North American Aviation. Together they produced more of the slab-sided behemoths than any American warplane ever.

How Ford's Willow Run Assembly Plant Helped Win World War II

President Roosevelt stunned millions of listeners when he announced during a May 26, 1940, fireside chat that government must harness the efficient machinery of America's manufacturers to produce 50,000 combat aircraft over the next 12 months to confront the approaching storm of global war.